This report is prepared by the Asian Downstream Summit team in Singapore.

Industry 4.0 and Smart Manufacturing will transform the oil refining, petrochemical and chemicals sectors into a connected, information-driven environment. Industrial IoT (IIOT), Industry 4.0, and Smart Manufacturing are all closely related and have similar objectives – improving manufacturing. However, both Smart Manufacturing and Industry 4.0 also look at improving manufacturing in the broader context of society and the environment, whether these improvements stem from science, engineering, informational technology (IT) or operational technology (OT).

Using real-time and high-value support systems, smart manufacturing enables a coordinated and performance-oriented manufacturing enterprise that responds quickly to customer demands and minimises energy and material usage, while radically improving sustainability, productivity, innovation and economic competitiveness.

This report talks about Industry 4.0 and Smart Manufacturing for the refining and petrochemical sectors.

What exactly is Industry 4.0?

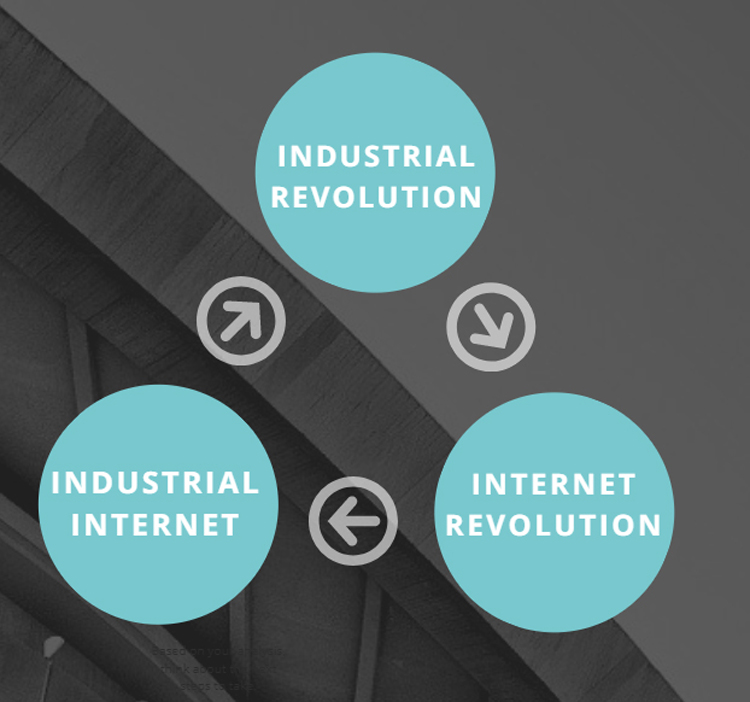

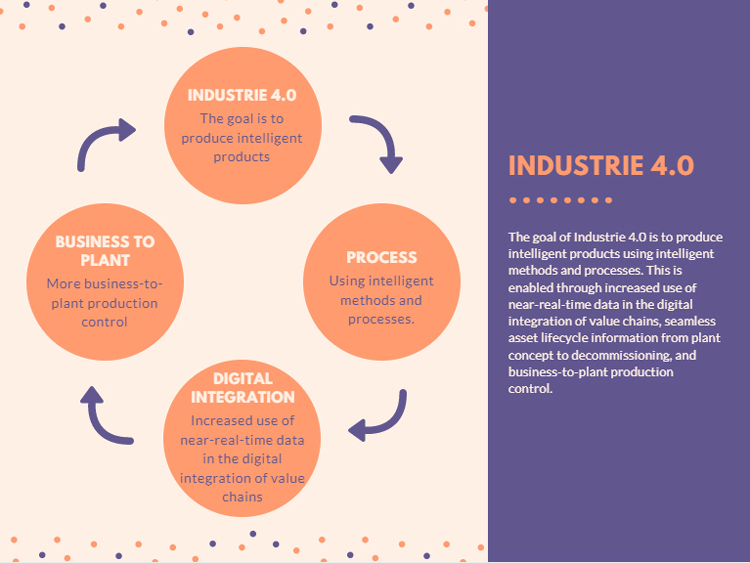

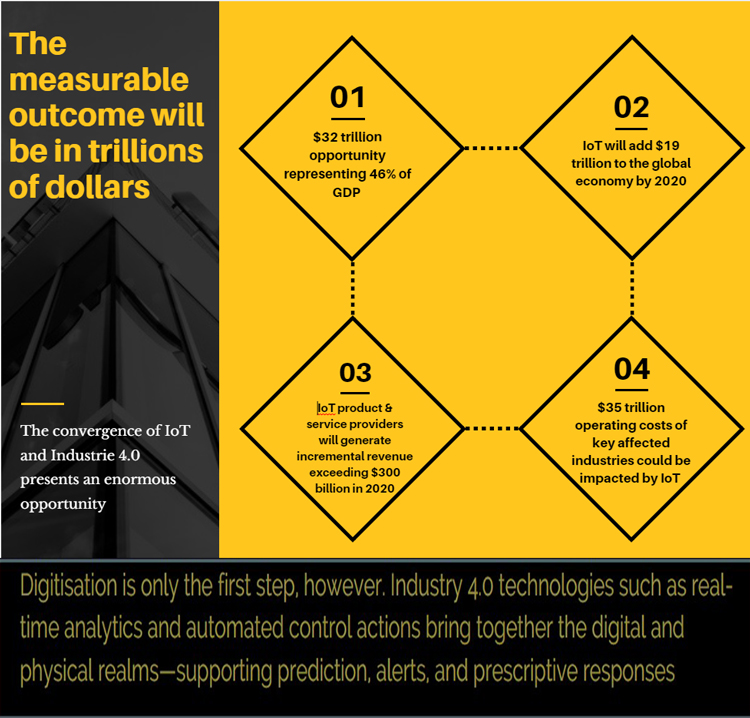

Industry 4.0 is the systemic transformation of manufacturing enabled by the convergence of physical-digital systems to improve quality, lower costs, and increase efficiency. Industry 4.0 combines digital and physical advanced technologies and has the potential to transform the downstream oil and gas industry.

Through the dual areas of business operations and growth, these technologies enable “smart” supply chains and factories, as well as create new business models.

Industry 4.0 enables companies to gain deep, real time understanding into their operations.

We are in the midst of the fourth industrial revolution, but what benefits will it have for oil and gas & chemicals?

From robots to cobots, Artificial Intelligence to Augmented Reality, analytics to machine learning – the fourth industrial revolution is upon us.

Industry 4.0 is already creating incredible opportunities for manufacturers, employees and their customers in refining and petrochemicals. New technologies are enabling industry leaders to maximise resources, empower employees and even predict breakdowns before they happen.

However, the true potential of Industry 4.0 will only be realised through smart manipulation of data. Manufacturers have recognised the potential of sensors and connected devices for some time, and as a result, they’re enjoying access to more relevant, real-time information than ever before. But such vast quantities of data can be tough to store, visualise and understand, let alone guide business decisions. Luckily, technologies like machine learning make it possible to turn this raw data into actionable insights.

Building a better future for manufacturers: Industry 4.0

With connected technology, advanced analytics and mixed reality simulation with technologies, our plants will never look the same, with 40% of operational processes becoming self-healing and self-learning by 2022.

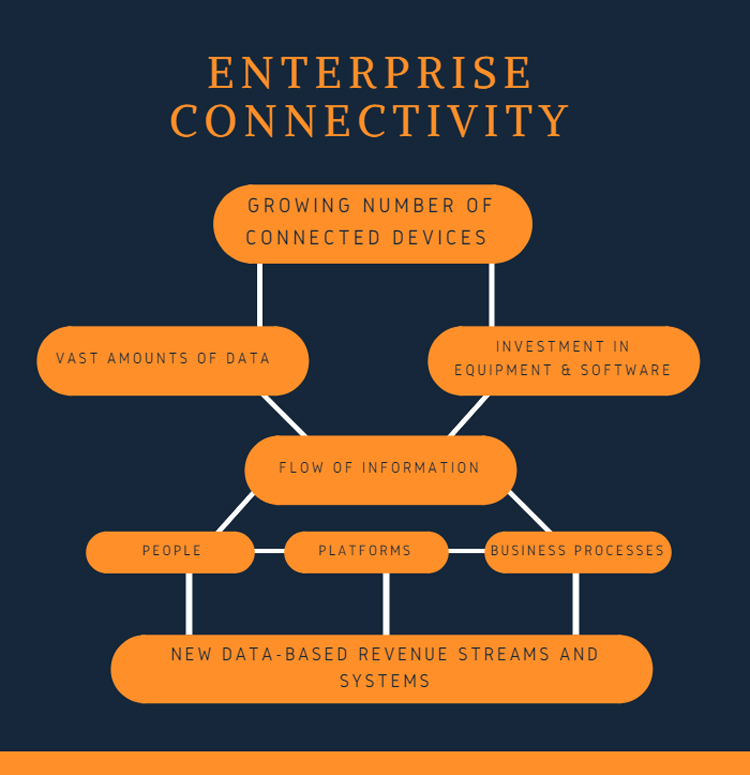

Growing number of connected devices create vast amounts of data. Operators are investing in equipment and software that allow this information to flow between different platforms, people, and business processes to create new databased revenue streams and systems.

As more operators embrace the power of Industry 4.0, it will become easier to align efforts to create “digital ecosystems” and connected intelligent systems across all parts of the supply chain that drive true business efficiency, productivity and innovation.

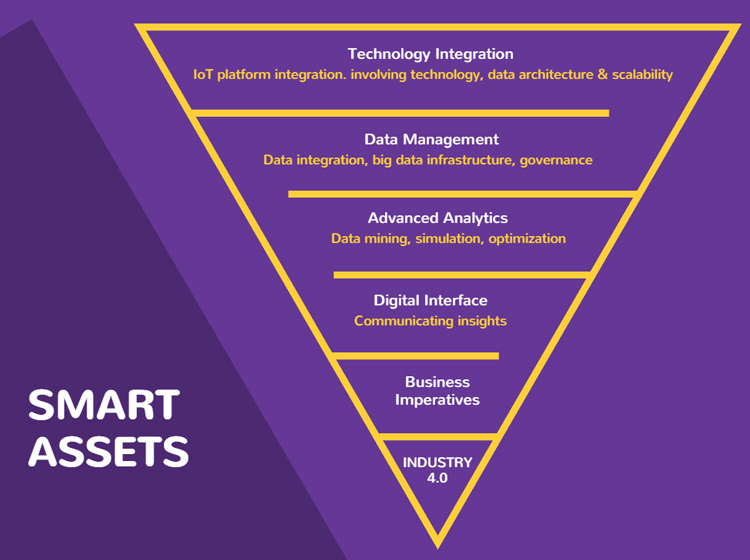

The solutions layer architecture: Enabling Industry 4.0 technologies and capabilities

In Industry 4.0, data plays a key role in connecting IT and OT. Data management, analytics, and automation, combined with domain knowledge in manufacturing and supply chain along with leadership support, are critical factors to enabling a company’s Industry 4.0 journey.

However, these factors can present challenges. It makes it difficult for organisations to know where to focus and what to prioritise, or even what capabilities should be put in place, to achieve their specific objectives. A structured series of capabilities, or a solutions layer architecture, can help executives plan and implement Industry 4.0 technologies.

The goal of this architecture is to enable the company to build a digital DNA the underlying sequence that brings together capabilities in different domains required for a digital transformation. The layers in this structure begin with technology integration, data management, and advanced analytics, which in the physical realm are manifested in the form of digital interfaces that are used to drive digital capabilities and, finally, the strategic imperative of the business.

Industry 4.0 is no longer a topic of the future

Industry 4.0 will impact the way refineries & petrochemical companies operate and grow their businesses, as they move towards providing value-added products and services to their customers. How fast and well companies perform will depend on the decisions they take today and the initiatives they commit to for the coming years.

A clear understanding of their strategic imperatives can enable them to plan their Industry 4.0 journey and help them identify how to integrate their digital and physical assets across different stages of the value chain. Operators can use Industry 4.0 technologies to enhance business operations via asset optimisation, process and energy management, and safety processes, while also thinking about ways to grow their businesses.

As companies face various challenges in their journey to Industry 4.0, it is critical that they prepare their technology and data landscape to support the evolving changes in their products, services, and, at times, new business models to create a competitive advantage for themselves in the long run. Beyond technology, however, the agility of people and organizations in adapting to change determines how effectively they adopt Industry 4.0.

About Asian Downstream Summit

Asian Downstream Summit is a well-recognised brand in South East Asia region and it has been running 10 successful editions (now in its 11th year), gathering over 7000+ refining and petrochemical industry professionals. The show constantly innovate and refresh its content through thorough research amongst the industry and strengthened relationship with the major international and regional operators.

Asian Downstream Summit will bring the operational excellence theme to another level by digging deep into the digital transformation & automation and how technologies can impact the regional and global oil & gas, refining, petrochemical and chemicals operators.

Asian Downstream Summit has been the anchor oil and gas event during Singapore International Energy Week (SIEW), an initiative of Singapore government that attracts 10,000 attendees every year. For more information on SIEW, visit www.siew.gov.sg