(Photo credit: iStockphoto)

In recent years, China has become one of world's biggest producers and consumers of household appliances and equipment. China's energy consumption is rapidly increasing as the economy is growing fast. With sustained economic growth and rising living standards, it is estimated that energy consumption will increase continuously.

The NDRC (National Development and Reform Commission) proposed and announced the first mid- to long-term special energy plan on June 2004. The plan specifically states clearly that energy efficiency of products should achieve the world's highest level in 2020.

China's 2020 emissions target

China clearly overtook the US as the world's leading emitter of CO2 in 2008. To tackle the climate change issue, the Chinese government announced that the reduction target of CO2 emissions per GDP would be to cut 2005 levels by 40-45 percent come 2020.

Under this condition, energy efficiency standards and labelling have an increasing significance. This paper points out several shortcomings of Chinese S&L (standards and labelling) policies that prevent the realisation of full energy savings potentials, which include the time lag between standards setting and implementation, inconsistent efficiency evaluation methods, not incorporating regional differences, limitations in the items covered by the labelling scheme, and lack of sales promotion.

Based on these observations, the authors suggest modifying how one sets energy efficiency standards, using regional coefficients, streamlining evaluation methods, including more items under the labelling scheme, and introducing an energy-efficient appliance bestsellers programme to promote sales of highly energy-efficient appliances and equipment.

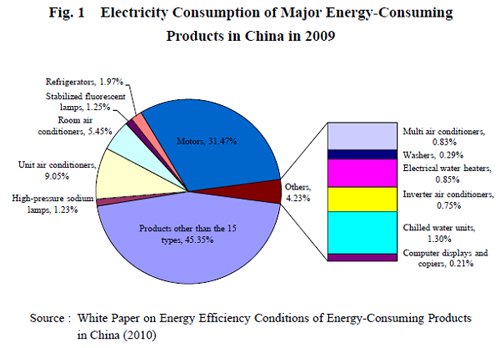

Electricity consumption of major appliances

During China's transition to a market-based economy, its electricity consumption increased significantly. In 2009, total electricity consumption reached 3,297TWh in China, which is 14.6 percent of total energy consumption of the whole country. This is 5.96 percent higher than the preceding year, with the growth rate also increasing at 0.47 percent higher than the growth rate of last year.

The electricity consumption of 15 major energy-using products including appliances and equipment in 2009, was about 56 percent of the total electricity consumption.

Issues of energy efficiency standards and labelling

Energy efficiency standards and labelling have been adopted as effective methods of energy conservation policy. However, there are some problems in the current system and there exists a gap between standards and reality. Therefore, it has not fully achieved the expected energy savings. The following is a discussion regarding the standard formulation, implementation, and evaluation methods.

Gaps between standards and market

China's energy efficiency standards are minimum energy efficiency standards, which are determined by the energy efficiency of the products manufactured. However, it takes at least one year for the development of standards, and generally at least six months from announcement to implementation of the standard.

Meanwhile, as the competition among enterprises increases, technological development advances, and by the time the standard is implemented, the level set for the standard is often lower than the average levels of product in the market. Therefore, only limited numbers of products are phased out, and this leads to a gap between the efficiency level of the products in the market and the energy efficiency standards.

In addition to the time lag in the development and implementation of the standard, there is also a long interval in the update of the energy efficiency standards. After the publication of the first energy efficiency standard, though there are revisions of standards for some products, there are also products that the standards have never been updated for since the 1980s or 1990s. In the case of TVs, the first limited energy consumption and test methods were developed for black-and-white TVs in 1989. By the late 1990s, urban areas of China, where the TV ownership rate was higher, had already shifted to colour TVs.

However, the test methods for colour TV were published only 15 years later, in 2005. With the development of television technology, the market has converted into flat plasma and LCD TVs from conventional colour TVs. But the revision of the energy efficiency standards for television has not yet been carried out. In addition, energy efficiency standards for the ballasts of tubular fluorescent lamps still remain at the 1999 standard level.

Evaluation method

The evaluation method for energy efficiency is not always consistent even for the same product with different specifications. Looking at the example of room air-conditioners (ACs) in China, the evaluation methods of the energy efficiency for fixed non-inverter AC and inverter AC differ, and the method for comparison of the efficiency between the two types has not been established.

Limitations in items covered by labelling scheme

At present in China, there are 33 types of appliances and equipment, but only 22 types have been labelled. In other words, 11 types, or one-third of all types of appliances and equipment, have not yet been labelled.

Barriers to sales promotion

In recent years, the Chinese government has been strongly promoting the popularisation of energy-saving products through providing subsidies such as the Program of State Subsidy, subsidies for replacing old products for new ones, subsidies for high-efficient lighting products, and so on. Such government subsidies temporarily attained better results. However, the problem of how to promote the diffusion of energy-saving products after subsidies are over still remains.

Along with the implementation of energy efficiency standards and strong market competition, the policies for diffusion of energy-saving products in the market do not keep pace with implementation.

Prospects

In view of the formerly discussed issues, we should try to seek solutions to solve them.

First, the development, implementation and update of energy efficiency standards should be arranged rationally and in a timely manner. Generally, the revision of minimum energy efficiency standards is to be adapted to the standards that should be attained three to five years later. This is so enterprises are able to put out products meeting the scheduled standards into market, which is called predetermined standards. The implementation of the standards would be beneficial for enterprises' technological progress. Also, by combining the standards with enterprises' technology, the gap between Minimum Energy Performance Standards (MEPS) and market sales would vanish.

Second, the same commodities group should not set up different energy efficiency standards, and the evaluation methods also should be unified in order to provide consumers with the correct evaluation, which enables consumers to make well-informed decisions. Supposing that ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission) are to be integrated into one system in China, it will not only provide more chances for Chinese commodities to gain entry into the international market, but also promote the development of energy efficiency standards in China.

Third, considering the wide land area of China, it is important to adopt the evaluation methods accommodating regional differences. In the case of Japan, regional coefficients for APF are being set in order to enable the calculation of annual electricity consumption according to the region. Consumers can use the regional coefficients in choosing different commodities.

In China, the evaluation methods based on regional differences will present actual information of energy efficiency and energy consumption to customers and encourage them to make correct choices.

However, strict energy efficiency standards cannot ensure the wide diffusion of energy-saving appliances and equipment necessary to achieve energy conservation. The energy efficiency standards and labelling should be used together. It is not only necessary to diffuse energy-saving products in the market through labelling, but also to increase the number of products that require energy-efficiency labelling.

Finally, along with the expansion of labelling and improvement of energy efficiency standards, in order to realise the benefits of these policies in the markets, it would be necessary to introduce policy measures to encourage the energy-saving product bestsellers. By placing such bestsellers as leaders in diffusing energy-saving products, energy-saving products can be promoted in the market.

Therefore, good policies in China are able to improve the cognition of labelling and awareness of energy saving.

This article was reproduced with permission from The Institute of Energy Economics, Japan. You can find the full report here.

BY : Xialu Zhou, Hiroki Kudo and Suzuko Tanaka, IEEJ